ZAIN AL-A’EMAL COMPANY – ZAC – is committed :-

- Complying with health. Safety and environment legal requirements and consider it the absolute minimum standard and where appropriate committed to implementing high standard level.

- Standard level.

- Preventing occupational injury, incidents, ill health, and diseases.

- Minimizing the environmental impact of its projects and activities by protecting the environment (air, water. Land, natural resources, flora fauna, and human being and their relationship).

- Creating a positive HSE culture through leading by example and promoting safe working practices.

- Enabling consultation and participation with all workforce and stockholders.

- Establishment and achieving HSE objectives to improve the HSE management system implementation.

- Maintain appropriate communication channels with all interested parties to ensure sufficient information concerning occupational health, safety, and environment.

- MERP- Medical Emergency Response Plan.

We are committed to the safety rules followed by customers, and do not allow any violation of these rules while entering the work site.

Safety Site Management:

Staff Selection and O-Chart.

Method Statement & Risk Assessments.

Employee Communication and Consultation.

Competency and Training- Specific Training.

Conduct Medevac Drill & involved with site staff in a project.

Incident and Accident Reporting.

Environmental Impact Assessment.

Permit to work implementation.

HSE Inspections and Testing Plan.

Equip.& Material Site Entry Permits & Tagging.

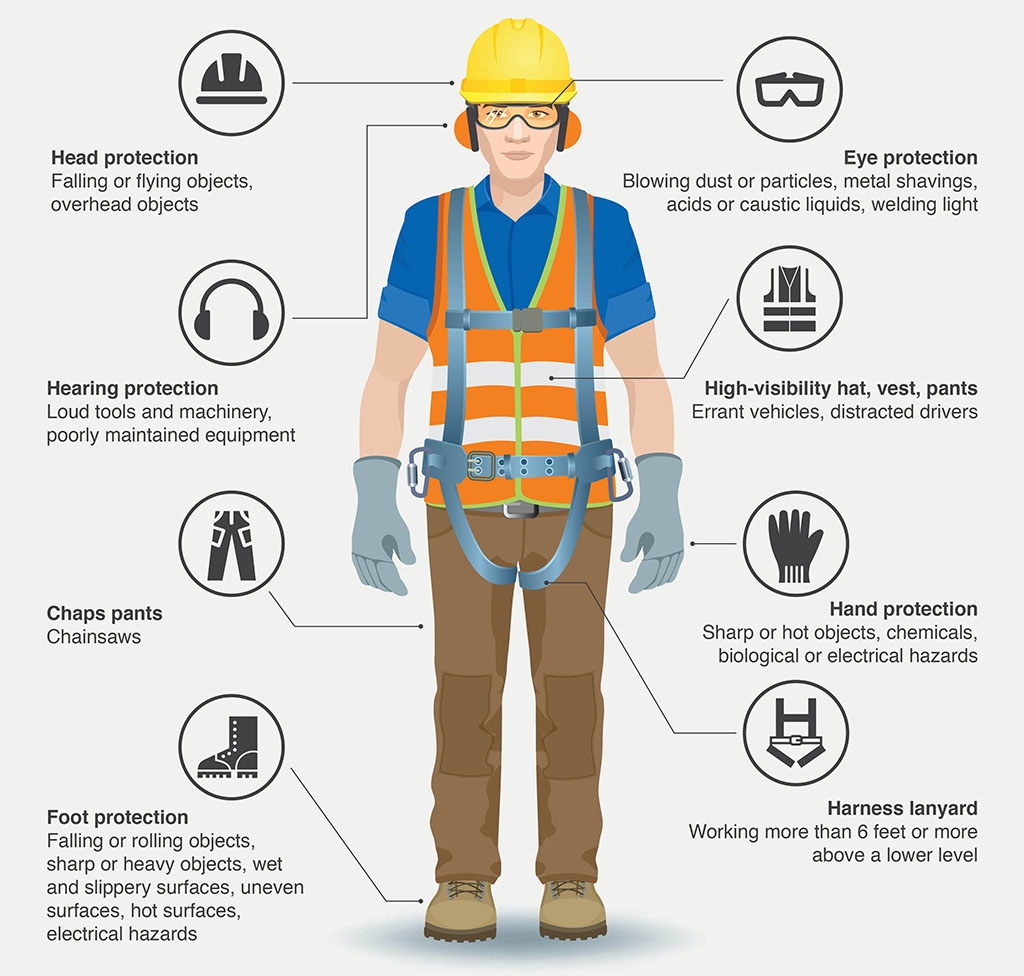

Site Entry – with wear the Personal Equipment Protection- PEP.

Waste Management arrangement.

Emergency Preparedness and Response Plan.

Project – HSE Operational Controls Includes:

Confined Space Procedure. Provide Safety Induction for all new staff.

Work at height procedure.

Traffic Control, and Security Management Plan.

Safe Lifting procedure.

Site Firefighting Plan.

Personal Protective Equipment.

Hazardous Substances inventory control.

Work Equipment.

Assembly point area.

Isolation procedures and Safe System of works (LOTO).

Supervision – HSE site supervisors.

In-house Quality Procedures:

QUALITY MANAGEMENT SYSTEM

Prioritizes quality by seamlessly integrating its robust Quality Management System (QMS) across the organization. This involves clear documentation, structured roles, and proactive measures, fostering a culture of continuous improvement for high-quality project delivery.

Workers are responsible for:

- Ensuring their own personal health and safety, and that of others in the workplace.

- Complying with any reasonable directions (such as safe work procedures, wearing personal protective equipment) given by management for health and safety.

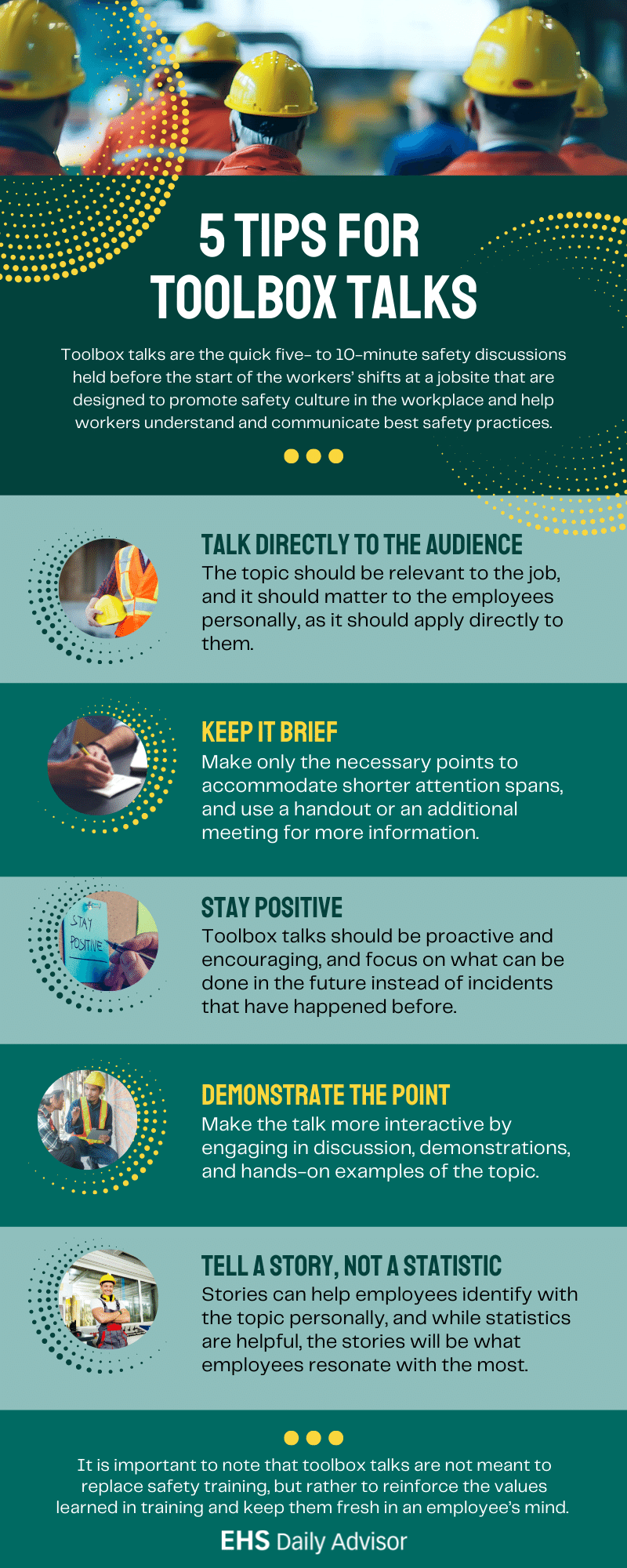

- Attending Toolbox meeting before start the work.

All in site responsible to report any accident, injury, Near-miss, and Hazard.

We expect visitors and contractors to:

- All visitors and contractors must inform site project manager before come.

- All visitors and contracts must flowing all instructions in site work.

- All must visitors and contractors must wear PPE mandatory to inter site work.